Small Jobs Slowing You Down?

Change in the printing industry happens rapidly at times, while other trends seemingly take years to mature. A few trends have been at work for several years, but many printer service providers (PSPs) see this impact on their business—the need to manage, produce, and maintain a higher number of smaller jobs. Technology improvements across all equipment meant that PSPs could produce work faster and more cost-effectively. The on-demand transition of printing meant that customers could order fewer quantities but more frequently. Brands and businesses also increased customization and personalization to account for relevance and accuracy in targeting consumers and customers.

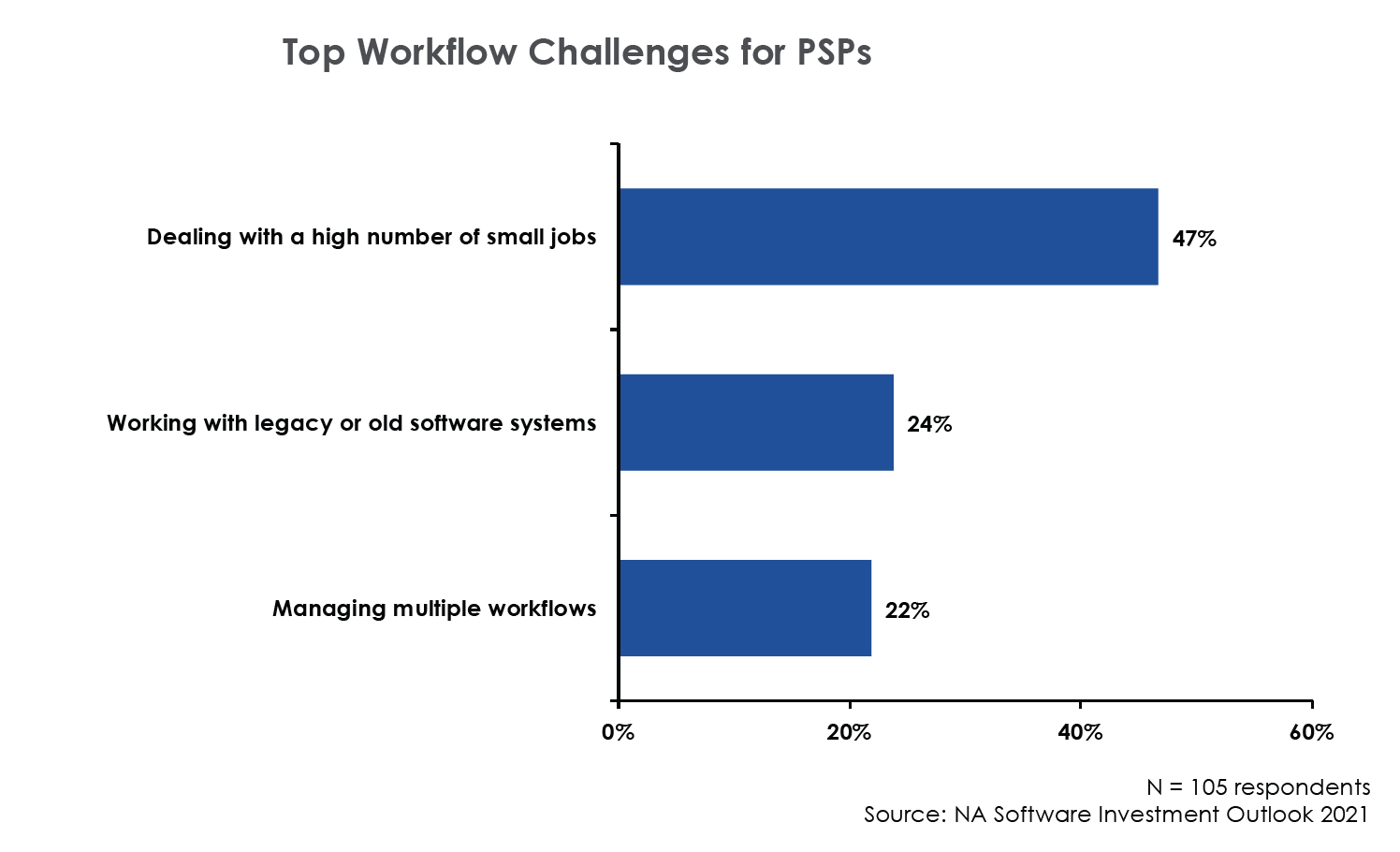

Top Workflow Challenges for PSPs

The result is that the number of small print jobs has been on the rise, while many of the preproduction processes have remained unchanged. Smaller jobs need better, automated processes to minimize production costs due to the lower price points and (in many cases) profit margins. Using the same processes as the work mix transitions from high-run to short-run jobs leads to production chaos, not to mention unrealized financial effects. As a result, nearly half of printers today have difficulty keeping up with short-run production.

Planning and Job Optimization are Needed

The answer to the increase in smaller jobs is better planning and optimization. Planning ensures the work is effectively using all available resources to maximize productivity and minimize costs.

- Maximize equipment usage by combining jobs with similar press run characteristics like paper and inks.

- Optimize materials usage by calculating the best equipment, based on format size and running costs, for the least amount of waste per sheet and over the entire press run.

- Save labor costs by removing the time needed to build and plan the best production scenario manually.

The traditional method of planning and imposing artwork for the printer has become labor-intensive and relies heavily on staff expertise and knowledge. Hours could be spent creating a production plan based on the known mix of work and job criteria, only to be disrupted as jobs were added or changed—not to mention interruptions from unavailable equipment due to capacity issues, maintenance, or repair.

Reach Maximum Velocity with Intelligent Planning

PSPs can better manage the influx of smaller jobs and optimize production by using intelligent planning software. The range of planning and smart imposition solutions from Tilia Labs ensures you are getting the best use of your equipment, substrates, and labor costs— whether you offer commercial, label, folding carton, or wide format printing. The software’s Imposition AI understands the mix of jobs, looks across all available printing methods and calculates thousands of potential production layouts in seconds, not hours. Select the best plan based on costs, waste, service level agreement (SLAs), and your overall production schedule. Intelligent planning and imposition are critical for getting out of the small job slowdown and reaching maximum velocity in your printing operations.

Author: Greg Cholmondeley is the Director of Keypoint Intelligence’s Production Workflow Consulting Service, which helps vendors define their future through consulting, market analysis, research, and forecasting. He also works directly with print service providers to improve their operations through workflow audits based on workflow journey mapping and the five stages of smart print manufacturing.