The Difference Between Getting Work In and Getting It Out

Keypoint Intelligence’s research has shown that commercial print services providers (PSPs) have broadly adopted e-commerce and print marketing information system (MIS) solutions. However, they are lagging in implementing print-stream automation such as scheduling, impositioning, ganging, and routing. This means that print shops are becoming more adept at productively getting more jobs into their shops but are not as efficient in moving orders through the production process.

This data is significant for a few reasons:

- Only about half of the PSPs have digital workflow management solutions—meaning that the remaining companies are probably still using the same paper job ticket and job jacket methods that have been around since the 1950s.

- The issue is probably more profound than these numbers indicate. After all, not everyone who has a print MIS system uses it to track jobs through the shop, and not every job comes through a web-to-print solution.

Software Ownership by General Print Services Providers

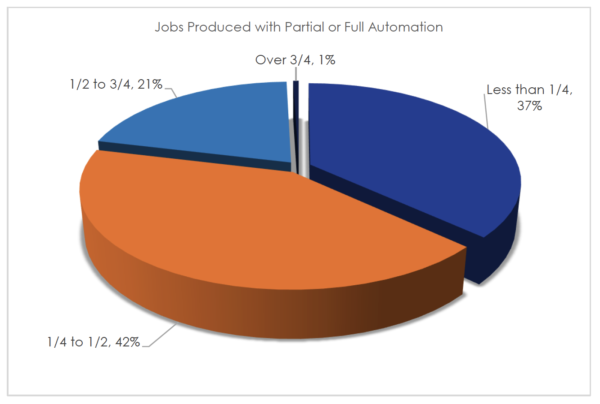

The recent Keypoint Intelligence Western European research study confirms this observation, where 80% of the respondents produce fewer than half of their jobs with even partially automated workflows. These findings indicate that few companies utilizing point solutions for specific production tasks are using them to automate their workflows.

General PSP Jobs Produced with Partial or Full Automation

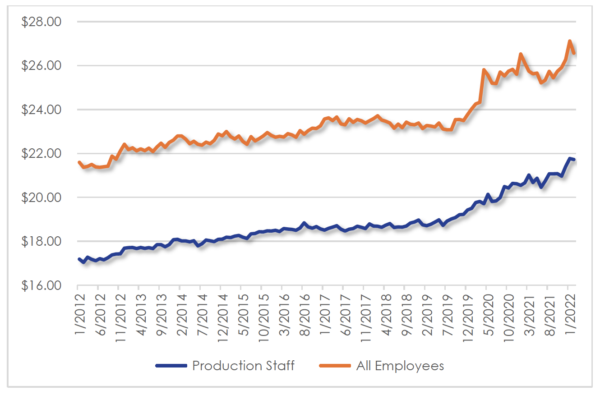

The Growing Importance of Automation

Automating production workflows (not just individual tasks) is more important than ever. For many years, labor rates were relatively flat in the printing industry, and then they began rapidly escalating starting in 2019. According to the US Bureau of Labor Statistics, average printing industry hourly wages increased at a 5.4% compound annual growth rate (CAGR) from 2019 to 2022. And these numbers are the base salary figures—not the fully-loaded budgeted hourly rate (BHR) that includes vacation, holidays, and benefits.

This rapid rise in labor cost—along with the challenge and expense of hiring, training, and retaining skilled workers—means that handling print jobs in an automated fashion has gone from a competitive advantage to an operational necessity. That is not to say that PSPs should all become lights-out operations as this would transform the industry into a solely price-driven commodity market that is not what most PSPs or their customers want.

Instead, PSPs need to automate the functions that do not provide competitive differentiation and use their people to deliver the capabilities that set them apart. No customer cares whether people or software handle job routing, impositioning, preflighting, or other production tasks. To be honest, they probably do not know how PSPs produce their work. They want people to understand their needs, recommend better solutions, catch mistakes, and ensure that they get what they want.

Average Printing Industry Hourly Wages

Automation Is More Than Hardwired Job Processing

The core reason general PSPs produce so many jobs using manual workflows is that creating automated workflows can be challenging for the wide variety of work they handle and the whole idea of change is daunting. Defining how to imposition and route a job to the appropriate press and media can result in hundreds of possibilities. Add in job ganging and routing to multiple presses to increase productivity, and those numbers can explode into thousands or millions of possibilities.

Of course, limiting customers to a number of document sizes and options can simplify the process. However, while that might work in a commodities operation, offering customers precisely what they want is typically a key differentiator. PSPs often balance flexibility with efficiency by automating straightforward, standardized jobs like business cards while manually handling more complex work. While this approach certainly helps, new technologies make automation more cost-effective for a greater variety of jobs.

Author: Greg Cholmondeley is the Director of Keypoint Intelligence’s Production Workflow Consulting Service, which helps vendors define their future through consulting, market analysis, research, and forecasting. He also works directly with print service providers to improve their operations through workflow audits based on workflow journey mapping and the five stages of smart print manufacturing.